For Mercedes-Benz systems that are listed above only! NOTE: Basic Tester is available without extras below. This will NOT WORK on the M110 6-cylinder as well as the M102 4-cylinder engines. Fully pressure tested before shipping. If you own or are restoring a 6 or 8-cylinder 1970 to 1993 D-jetronic, K-jetronic, or KE-jetronic fuel-injected Mercedes, a fuel-system pressure tester is a must-have! This complete kit will allow you to do a full system pressure test yourself with the very detailed video instructions included. Why buy a tester that you do not know how to hook up and may not even be accurate? I guarantee that every single one you buy from China on Amazon will leak at least at one fitting, and the gauge will not be accurate. Kent makes sure that this tester is accurate and will not leak. And with the detailed, multipart video series included (combined 3 hours long), you will learn how to hook this up and make the tests YOURSELF! Sorry, it does not include the fittings necessary to test some 2.3-liter 4-cylinder engines. FIT

Product Details

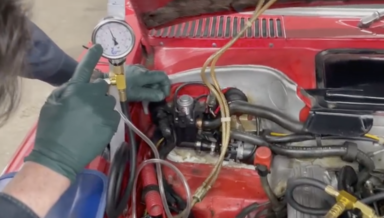

The tester has two basic configurations. The "T" configuration if for the 1976 to 1993 Bosch C.I.S. fuel injection systems. The straight connection will allow you to test 1970 to 1975 D-Jet electronic fuel injection ( wires to the injectors).

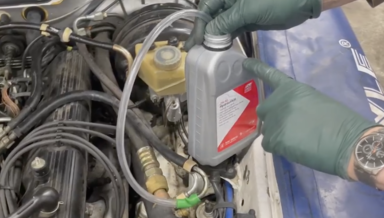

Below are the parts in the kit that you will need to test K or KE-Jetronic (CIS) fuel injection. You will get the correct fittings and a thin 14mm wrench to install them on the fuel distributor. The included jumper wire will help you on some engines to get the pumps to run without having to start the engine.

Pictured below are the extra parts for testing D-Jetronic. They will be in an extra bag marked D-Jet. These will allow you to hook up to the fuel rail in the best position.

The attached liquid-filled gauge reads from 0 to 160 psi. The most pressure you will be dealing with with max out at around 90 psi. This gauge is accurate and takes more abuse than a standard gauge around engines, but you still need to be careful not to drop or bang it around.

7/26/25 Product revision:

We have modified the fuel pressure release capture bottle to make it permanently attached to the release clear hose. This will increase safety and efficiency. We had to drill a very small hole at the top of the cap to vent pressure; therefore, please keep the bottle upright during testing.

IMPORTANT NOTICE: There is a difference now from what you will see in Kent's video. NO MORE QUICK DISCONNECT. If the internal seal fails it will leak a lot of fuel. So, the applicable connection hose is now connected with a screw-on fitting. This will eliminate the potential for any fuel leaks.

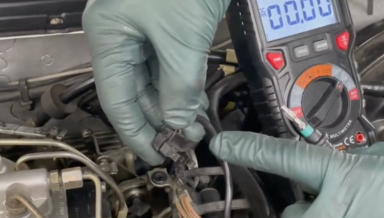

Think safety. Glasses and gloves are included. Always use them when working with high-pressure fuel systems. AND have a fire extinguisher on hand.